Why Choose Us

The Nichwell Solutions advantage.

When you select Nichwell Solutions as your technology provider, you'll be placing your IT infrastructure in the hands of experienced, trained professionals. We take a different approach and the results are clear. People love our team and the services we provide. | |

| Knowledgeable Experts.A certified staff of technicians and engineers.We lower your support costs by correctly diagnosing and fixing issues the first time and by providing effective preventive maintenance to help you avoid expensive downtime and repairs. Our 100% Nicehwell-based team consists of experienced, seasoned professionals certified by Microsoft, Citrix, Dell, VMWare, Veeam and CompTIA. We are your IT department. |

Custom-Built SolutionsDedicated account representative and support system for your organizationOur sales team is not influenced by commissions, manufacturer incentives or quotas because that's not how we do business. We explore your operations, carefully evaluate your security, establish your monitoring and technology needs, then provide a tailored proposal. Because our only interest is a satisfied long term client, you can be sure we're on your side and our solutions will always revolve around you. |  |

| No OutsourcingEvery service is owned, managed and backed by our in-house professionals.When you purchase a re-sold service and then that service has a problem, response and resolution times can suffer. That's why we host our own servers in carrier-class, US-based data centers and we don't resell 3rd party hosted services to our clients. We're control freaks. Say goodbye to delays, excuses, finger pointing and blame-games. If we offer it, we support it. It's as simple as that. |

Honest PricingRelationships are more important than a quick buckNichwell Solutions has a high client retention rate. This is partly because people love our team, but it's also because we take the time to assess your needs and propose affordable solutions that grow as you grow. Our clients view us as a partner, not a vendor. We help you reach your goals, we help you understand and leverage technology, and we believe in the benefits of building lasting relationships. |  |

| Client ServiceThe key to our client service is our seamless integration of deep industry and functional expertise with tools and capabilities to support execution and make change happen—on a global scale. |

| |

α-1800V Vacuum Glove Box With Manual Operation Purging

α-1800V Vacuum Glovebox With Manual Operation Purging | |||

|---|---|---|---|

| External Structure |    | ||

| Chamber Capacity | Approximately 24.7 cu.F.t (0.7 m³) | ||

Overall Dimensions | 98.4" L x 28.7" W x 62.6" H 2500mm (L) x 730mm (W) x 1590mm (H) | ||

| Glovebox Vacuum | ≤-1bar | ||

Overall Weight | 460 kg (1012 lbs) | ||

| Electrical Voltage | • 230 VAC/50-60 Hz, 10 A • 115 VAC/50-60 Hz, 20 A • 100 VAC/50-60 Hz, 20 A | ||

Glovebox Chamber | |||

| Description | Material | Stainless Steel Type 304 (USA), 5.0 mm in thicknes | |

Internal Dimensions | 70.9" L x 23.6" W x 25.6" H 1800mm (L) x 600mm (W) x 650mm (H) | ||

Inclined Front Window | Material | Acrylic, 15.0 mm in thickness,Lexan (polycarbonate) 15 mm in thickness upon request | |

Dimensions | 69.7"Lx15.0" W 1770mm (L) x 380mm (W) | ||

Glove Ports | Tecaform | 220 mm(8.6") in diameter, O-ring sealed |

|

Material | Hard aluminum alloy or polyaldehyde upon request | ||

Gloves | Material | Butyl rubber | |

Thickness | 0.4 mm,(standard) 0.8 mmupon request | ||

HEPA Filters | • Inlet and outlet filters eliminate particles with the size > 0.3μm | ||

| Lighting | • Fluorescent lamp, front mounted | ||

| Leak Rate | Typically · by oxygen leak decay test method according to ISO 10648-2: 1994, · by Pressure Change Test Method according to ISO 25412 | ||

Gas Purification System | |||

| Description | • Automated removal of H2O and O2 • Single column, automated column regeneration; dual purification columns (optional) • Enclosed stainless steel loop for gas recirculation and purification | ||

| Operating Gas | Working gas | Nitrogen, Argon, or Helium (purity >99.999%) | |

Column regeneration gas | Mixture of H2 (5-10%) and working gas | ||

Vacuum Pump | Description | Rotary vane pump, installed with oil mist filter, oil circulator, and automatic gas ballast control; dual-stage. Or dry pump upon request |   |

Pumping rate | 7.0 CFM (12 m³/h) | ||

Ultimate vacuum | -3 mbar | ||

Circulation Unit | Material | Integrated blower, oil-free, highly efficient | |

Flow Rate | 47 CFM (80 m³/h) | ||

| Leakage Rate | • Leak rate -5 mbar l/s | ||

| Valves | • Electro-pneumatic DN 40 | ||

| Leakage Rate | Typically · by oxygen leak decay test method according to ISO 10648-2: 1994, · or by Pressure Change Test Method according to ISO 25412 | ||

LCD or LED Display | LCD, Pressure, O2 and H2O value is logged for 24 hours | ||

Antechamber | |||

| Main Antechamber | Material | Stainless Steel Type 304; 6.0 mm in thickness | |

Internal Dimensions | 15.7" L x 9.8" W x 9.8" H 400mm (L) x 250mm (W) x 250mm (H) | ||

Vacuum | 1 x 10-2 mbar | ||

Purging System | |||

Function | By setting up the purging time and pressure, the system automatically purges the chamber | ||

Analyzer | |||

O2-Analyzer | Dimensions | 8" L x 3" D x 2.4" H 205mm (L) x 80mm (D) x 60mm (H) |   |

| Measurement Range | 0 to 1000 ppm (V) | ||

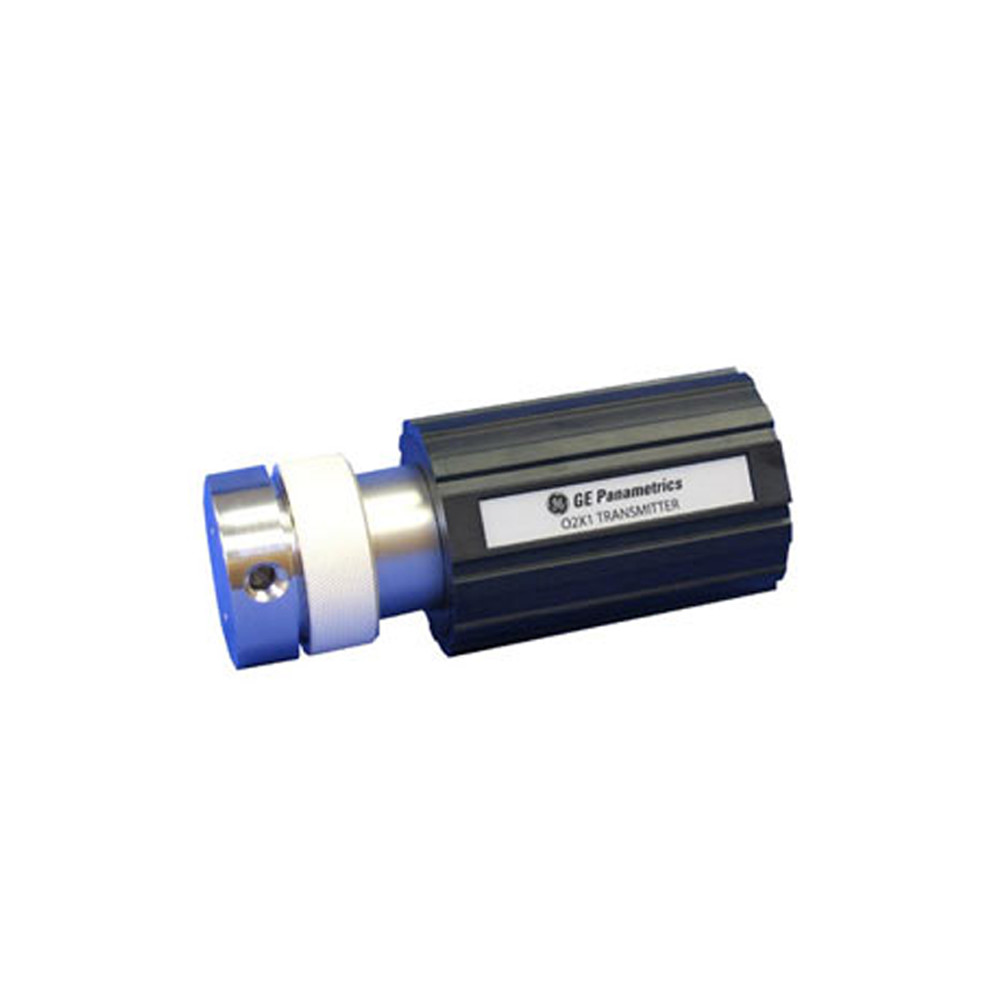

Other Analyzer | GE oxy.IQ™ Oxygen Transmitter upon request | ||

H2O-Analyzer | Dimensions | 8" L x 3" D x 2.4" H 205mm (L) x 80mm (D) x 60mm (H) |   |

Measurement Range | 0 to 500 ppm (V) | ||

Other Analyzer | GE VeriDri™ Dew-Point Transmitter | ||

Solvent Purification System | |||

| Description | Column Material | Stainless Steel Type 304 (USA); 3.0 mm in thickness | |

Inside Dimensions | 8.6"(Φ) x 17.7"(H) 220mm (Φ) x 450mm (H) | ||

Packing Material | High-quality activated carbon | ||

Optional Components | |||

| Vacuum feedthrough with two valves | Stainless Steel Type 304 | ||

Electrochemical signal feedthrough | 4 or 8 pins, Stainless Steel Type 304 | ||

Freezer | Location | Integrated on the side panel of the glovebox | |

| Inside dimensions | 16.6" H x 10.5" W x 6.4" D 423mm (H) x 266mm (W) x 162.5mm (D) | ||

| Capacity | 18 L or 32 L, 5 shelves with adjustable height | ||

Minimum Temperature | -35 ℃ (-31℉) | ||

Microscopes with CCD Camera Systems | • 10x, 20x, and 40x targets, 5.0 M CCD | ||

| Cold well with cover | Capacity | Diameter: 6.3″ (160 mm) Depth: 7.9″ (200 mm) | |

Minimum Temperature | -120℃ (-184℉) | ||

Dual Purification Columns | More efficient to remove oxygen and moisture | ||

Organic Solvent Absorber | Regenerable, more efficient to purify organic solvent | ||

| Cooling Fan | Accelerate the gas flow in the glovebox chamber | ||

Heating Element | Installed in Main Antechamber; Maximum 200 ℃; Temperature control ±1℃. | ||

Other Intormation | |||

| Compliance | UL certified, ISO9001 certified, and CE certified | ||

| Warranty | • One year limited warranty with lifetime support • Rusting and damage due to improper storage condition or maintenance are not covered by warranty • Gloves are consumable items and are NOT covered by warranty • The Oxygen Sensor is a consumable component NOT covered by warranty. Please follow the videos below for proper operations 1) Replacing a worn unit 2) Storing the sensor to ensure maximum longevity when not in use | ||

Application Notes & Warnings | • The interconnections between the glove-box chamber and the gas purification system must be unimpeded during the purification cycles • The use of corrosive gases is prohibited because they will damage the water and oxygen sensors • Regularly perform regeneration to maintain the optimum purification efficiency • The O2 removing rate is largely dependent on the type of purging gas used. For faster chamber purging process, Nitrogen is preferred over Argon due to its lighter mass • Corrosive liquid (such as LiPF6 electrolyte) must be sealed in a container inside the glove box. Otherwise, liquid vapour may condense and corrode the steel chamber and purification pipeline | ||