FREE:888-999-6186

CALL:541-666-2111

α-1500A Acrylic Glove Box With manual operation Purging

α-650A Acrylic Glove Box With manual operation Purging | |||

|---|---|---|---|

| External Structure | |||

| Chamber Capacity | Approximately 10.6 cu.F.t (0.3 m³) | ||

Overall Dimensions | 78.7" L x 33.5" W x 31.5" H 2000mm (L) x 850mm (W) x 800mm (H) | ||

Overall Weight | 640 kg (1400 lbs) | ||

| Electrical Voltage | • 230 VAC/50-60 Hz, 10 A • 115 VAC/50-60 Hz, 20 A • 100 VAC/50-60 Hz, 20 A | ||

Glovebox Chamber | |||

| Description | Material | Acrylic , thickness 10 mm | |

Internal Dimensions | 61" L x 23.6" W x 25.6" H 1500mm (L) x 600mm (W) x 650mm (H) | ||

| Glove Ports | Tekaform | 220 mm(8.6") in diameter, O-ring sealed |

|

Gloves | Material | Butyl rubber | |

Thickness | 0.4 mm,(standard) 0.8 mmupon request | ||

HEPA Filters | • Inlet and outlet filters eliminate particles with the size > 0.3μm | ||

| Lighting | • Fluorescent lamp, Top mounted | ||

| Leak Rate | Typically · by oxygen leak decay test method according to ISO 10648-2: 1994, · by Pressure Change Test Method according to ISO 25412 | ||

Antechamber | |||

| Main Antechamber | Material | Acrylic , thickness 20 mm | |

Internal Dimensions | 9.8"(L) x 9.8"(W) 250mm (L) x 250mm (W) | ||

Vacuum | 1 x 10-2 mbar | ||

Purging System | |||

Function | manual operation | ||

Analyzer | |||

O2-Analyzer | Dimensions | 8" L x 3" D x 2.4" H 205mm (L) x 80mm (W) x 60mm (H) |   |

| Measurement Range | 0 to 1000 ppm (V) | ||

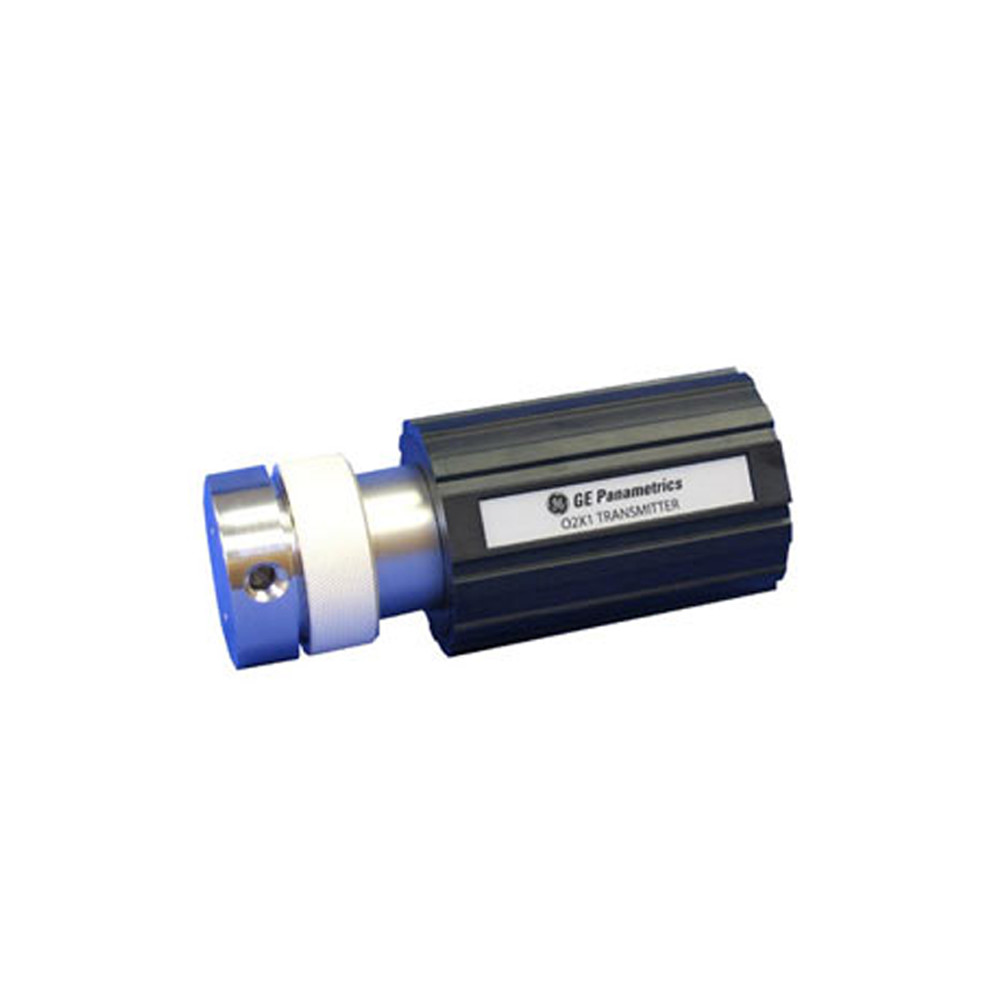

Other Analyzer | GE oxy.IQ™ Oxygen Transmitter upon request | ||

H2O-Analyzer | Dimensions (mm) | 8" L x 3" D x 2.4" H 205 (L) x 80 (W) x 60 (D) |   |

Measurement Range | 0 to 1000 ppm (V) | ||

Other Analyzer | GE VeriDri™ Dew-Point Transmitter | ||

Optional Components | |||

| Vacuum feedthrough with two valves | Stainless Steel Type 304 | ||

Electrochemical signal feedthrough | 4 or 8 pins, Stainless Steel Type 304 | ||

Organic Solvent Absorber | Regenerable, more efficient to purify organic solvent | ||

| Cooling Fan | Accelerate the gas flow in the glovebox chamber | ||

Other Intormation | |||

| Compliance | UL certified, ISO9001 certified, and CE certified | ||

| Warranty | One year limited warranty, and lifetime technical support | ||

Exceptions | • Rusting or damage due to improper storage or maintenance • Consumable items such as gloves and oxygen sensors | ||

Application Notes & Warnings | • The interconnections between the glove-box chamber and the gas purification system must be unimpeded during the purification cycles • The use of corrosive gases is prohibited because they will damage the water and oxygen sensors • Regularly perform regeneration to maintain the optimum purification efficiency • The O2 removing rate is largely dependent on the type of purging gas used. For faster chamber purging process, Nitrogen is preferred over Argon due to its lighter mass • Corrosive liquid (such as LiPF6 electrolyte) must be sealed in a container inside the glove box. Otherwise, liquid vapour may condense and corrode the steel chamber and purification pipeline | ||