FREE:888-999-6186

CALL:541-666-2111

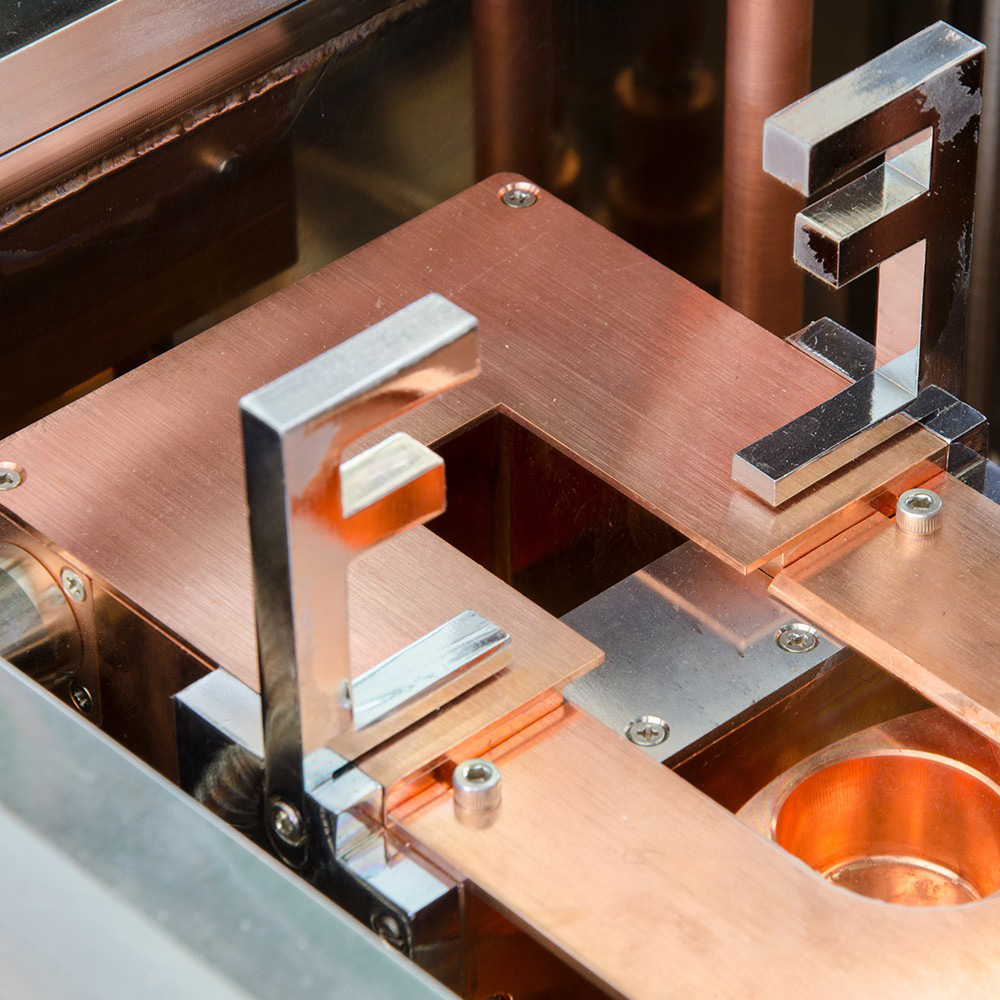

ATTO10-EG High Vacuum Electron Gun Coating and Glove Box System

Supporting standard single station glove box purification protection system

Ultra-low content of water and oxygen

Modular design of solenoid valve, lower leakage rate and easier replacement

Closed gas circulation, oil-free and vacuum

Cathode voltage 6KV-15KV, cathode heating power AC 3V + 3V, 60A adjustable

Cold crucible between beams 0 ~ 500mA, direct cooling crucible 0 ~ 1A

The crucible capacity is 4 × 17mL between 4 holes, 4 × 22mL with 4 holes, and 85mL with ring.

Magnetic field power X deflection current ± 2A adjustable, scanning frequency 10 ~ 250Hz; Y deflection current ± 2A adjustable, scanning frequency 10 ~ 250Hz

Starting vacuum degree 6.7 × 10-3 Pa

Crucible positioning (four-hole crucible) is automatic or manual point control

Crucible cooling water inlet temperature ≤25 ℃, inlet pressure ≥0.2MPa, water flow ≥8L / min

Grounding resistance of electron gun body

Technical Parameters

| Chamber | ||

|---|---|---|

| Description | Material: stainless steel 1.4301 (Sus Type 304), thickness 3 mm Size: 1200mm (L) x 750mm (W) x 900mm (H); 472" (L) x 295" (W) x 354"(H) | |

| Volume | 0.8 m³ | |

| Front window | Panel: 8 mm thick safety toughened glass or 10 mm thick polycarbonate (optional) Size: 1123mm (L) x 839mm (H); 442" (L) x 330" (H) | |

Glove port | Hard aluminum alloy material or polyoxymethylene material (optional) Caliber 220 mm, O-ring seal | |

Glove | Material: butyl rubber Thickness: 0.4mm or 0.8mm (optional) | |

| Filter | Outlet and inlet filters, filtration | |

| Illumination | LED lighting on top of front window | |

| Leak rate | Leakage detection shall be carried out in accordance with the oxygen method and pressure change method in ISO 10648-2:1994 / EJ / T 1096-1999 sealed box chamber - Part II: classification of tightness and related inspection methods, and the final acceptance test shall be carried out in accordance with the standard of primary tightness | |

| GP20 gas purification system (integrated or separated) | ||

| Description | Automatic removal of H2O and O2 Single purification column system, automatic regeneration (optional gp200 double purification column) Closed gas circulation pipeline | |

| Operating voltage | AC 230 V / 50-60 Hz, 10 A or AC 115 V / 50-60 Hz, 20 A (optional) | |

| Working gas | Working gas: N2, AR, he (purity ≥ 99.999%) Regeneration gas: H2 accounts for 5% - 10%, the rest is working gas (purity ≥ 99.999%) | |

| Vacuum pump | Specification: rotary vane vacuum pump with oil mist filter and air ballast control Flow rate: 12 m 3 / h (7 CFM), double substrate, vacuum degree | |

| Circulation unit | Oil free high speed fan Air volume: 80 m³/h | |

| Valve | KF40 high vacuum valve | |

| Leak rate | Leakage detection shall be carried out in accordance with the oxygen method and pressure change method in ISO 10648-2:1994 / EJ / T 1096-1999 sealed box chamber - Part II: classification of tightness and related inspection methods, and the final acceptance test shall be carried out in accordance with the standard of class 1 tightness | |

| Control cabinet size | 600mm(L) x 800mm(D) x 870mm(H); 236"(L) x 315"(D) x 343"(H) | |

Antechamber | ||

Main antechamber | Material | Stainless steel type 304 (1.4301), 3 mm thick |

| Size | φ 360mmx600mm (L) or φ 390mmx600mm (L) (optional); φ 142"x236" (L) or φ 154"x236" (L) (optional) | |

Vacuum degree | -2 mbar | |

Mini antechamber | Material | Stainless steel type 304 (1.4301), thickness 2 mm |

| Size | φ150mm x 330mm(L); φ59" x 130"(L) | |

Vacuum degree | -2 mbar | |

| Cleaning system | ||

| Description | With the corresponding time and pressure set, the system can automatically replace the gas in the box. | |

Analyzer | ||

Oxygen analyzer | Size | 205 mm(L) x 80 mm(W) x 60 mm(H) |

Measurement range | 0-1000 ppm | |

Other oxygen analyzer | GE oxy.IQ™ Oxygen Transmitter | |

Water analyzer | Size | 205 mm(L) x 80 mm(W) x 60 mm(H) |

Measurement range | 0-500 ppm | |

Other water analyzer | GE VeriDri™ Dew-Point Transmitter | |

Solvent purification system | ||

Description | Material: stainless steel 1.4301 (Sus Type 304), thickness 3 mm Internal dimension: 220mm (Φ) x 450mm (H) High quality activated carbon | |

Optional equipments | ||

Refreezer | Independent control system, integrated in the box side plate, temperature - 35 ℃, volume 18L or 32L optional Body 304 stainless steel plate, 5-layer variable partition R404 environmental friendly refrigerant, imported with original packaging | |

| Heating chamber | Main antechamber is equipped with heating system, with temperature of 200 ℃ and temperature control of ± 1 ℃ | |

Vacuum coating system | ||

|---|---|---|

| Description | Material: stainless steel 1.4301 (Sus Type 304), 5mm thick, all weld joints are connected by argon arc automatic welding technology; the inner surface is polished with mirror surface, and the outer surface is treated with three methods. Size: Φ 400 × h450mm; | |

| Volume | 0.056m³ | |

| Observation window | The door is equipped with a glass observation window (including anti pollution baffle) to facilitate the observation of working conditions. Meet the national standard of X-ray protection | |

Extra vacuum | ≤6. 67x10-5pa (2×10-7Torr) (after baking and degassing) | |

Vacuum recovery time | ≤6.67X10-4 pa (after baking and degassing) | |

| Interface | Three standard interfaces (φ 200) for expanding and installing molecular pump and plug-in valve; | |

| Four standard interfaces (cf35) are reserved for expanding functions; | ||

| Illumination | LED lighting is located at the side of the vacuum chamber to facilitate observation of the vacuum chamber | |

| Leak rate | Leakage detection shall be carried out for the box according to GB t 32218-2015, and the final acceptance test shall be carried out according to the standard of ≤ 1x10-10pal / s. | |

| Vacuum system | ||

| Description | Adopt "molecular pump + mechanical pump" high vacuum system: | |

| Molecular pump | Pumping speed: 1200L / s, a real quasi oil-free vacuum system, adopts down pumping to avoid the pumping weakness of the molecular pump and improve the pumping speed; the molecular pump is guaranteed for 5 years and provides direct replacement service for damage. *Optional imported molecular pump | |

| Vacuum pump | Specification: rotary vane vacuum pump with oil mist filter and air ballast control Flow: 36 m 3 / h (21 CFM), double substrate, vacuum *Optional dry vacuum pump | |

| Operating voltage | AC 230 V / 50-60 Hz, 10 A or AC 115 V / 50-60 Hz, 20 A (optional) | |

| Pumping speed | Extract from the atmosphere to 9×10-4Pa≤30min (expose the atmosphere for a short time and start to extract after flushing into dry nitrogen) | |

| Valve | Main valve: cc-200, high vacuum electric linkage gate valve; Front stage valve / bypass valve: gdq-40 high true air operated damper valve; | |

| Vacuum measurement | "Two low and one high" (two resistance gauges measure low vacuum, one ionization gauge measures high vacuum) digital display composite vacuum gauge, measuring range is from 1 × 105Pa to 1 × 10-5pa; it is displayed and controlled by PC, which can realize operation interlock linkage. *Optional imported wide range vacuum transmitter | |

| Vacuum measurement | Some of them are sealed with metal and some of them are sealed with fluororubber rings; | |

| Substrate stage | ||

| Description | The stage for placing samples is made of 304 stainless steel, and the substrate is directly above the evaporation source (full-automatic lifting function). The tooling is designed according to the size of the substrate to facilitate the user to fix the samples. The integrated high precision etching mask can be customized; | |

| Spin | The stepper motor is used to control the driving rotation, the magnetic fluid is sealed, the motor and the magnetic fluid are coaxial, and there is no loss of rotation, crawling and other situations. The stepper motor is controlled accurately, and the speed range is 0-30rpm continuously adjustable; | |

| Lift | It adopts stepping motor to control driving rotation, magnetic fluid seal, precise control, height range 0-100mm continuous adjustable; | |

| Mask | Drawer type structure, with a maximum load of less than 120 × 120mm samples, equipped with Japanese SMC pneumatic substrate baffle, fully automatic electrical linkage control. | |

Coating source | ||

Electron gun | Voltage | Cathode voltage 8KV, cathode heating power AC 3V + 3V, 60A adjustable |

| Crucible | Cold crucible between beams 0-500ma, direct cold crucible 0-1a The capacity of the crucible is 6-hole intercooling 4 × 17ml, 6-hole direct cooling 4 × 22ml, annular direct cooling 85ml The positioning of crucible (four hole crucible) is controlled automatically or manually Water inlet temperature of crucible cooling water ≤ 25 ℃, water inlet pressure ≥ 0.2MPa, water flow ≥ 8L / min | |

Number | 1 set | |

| Control system | ||

| Description | With windows operation platform, cotrl2000 control system and IPC + network technology, the parameterization setting of main parts of the whole machine, real-time monitoring, fault intelligent diagnosis and automatic monitoring of film thickness are realized. There are two modes of automatic and manual control. In addition to taking lofting products, other operation processes are all controlled by software on PC; friendly man-machine operation interfaces such as vacuum system, process setting, gas filling and discharging system are provided; parameters can be set by formula on industrial computer to realize setting, storage and printing of program process and equipment parameters. | |

| Features | It can effectively solve the accuracy, stability and reliability of coating. Perfect program interlock, complete anti misoperation design and protection; system water shortage, over flow pressure and other abnormal conditions alarm and implement corresponding protection measures. Rich I / O interface design is adopted to fully meet the functional requirements of expansion and external connected equipment. The display controls the door opening / closing of the coater. Coating process, process, film thickness, convenient and save printing. | |

Film thickness monitoring and control system | ||

| Description | The quartz crystal diaphragm thickness controller is used, and the water-cooled diaphragm thickness probe is installed near the substrate platform and connected with the industrial computer. The film thickness meter is used to monitor the coating rate and final thickness in real time with an accuracy of ± 1a (0.1nm). The real-time information is fed back to the industrial computer. If the coating reaches the set thickness, it can automatically control the power supply, stop coating and realize the purpose of automatic film thickness control. | |

| Range | Monitoring thickness range: 1 Å ~ 99 μ 9999 Å, resolution: 1 Å | |

Features | The coating process, process and film thickness are all set on PC, which can realize the automatic control of the whole process. The coating process can be set on PC and the data can be recorded. | |

Water cooling system | ||

Description | The cooling water circuit is 8 in and 8 out, and the main water inlet is controlled by water pressure relay. The total water inlet and outlet are connected to 1p refrigeration cycle water machine, with the temperature control range of 10 – 25 ℃. Provide stable cooling water for target, metal source, molecular pump and magnetic fluid to ensure stable operation of equipment. | |

| Other instructions | ||

| Product certification | ISO9001 certification、CE certification、UL certification | |

| Application considerations | Please refer to the danger, warning, caution and other clauses in the manual for details | |